You need to upgrade your Flash Player

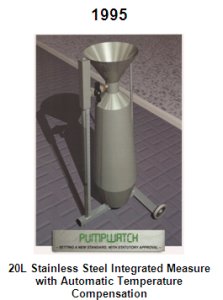

About PUMPWATCHPUMPWATCH Ltd was started in 1995 by Mr. Henry B Sisk as a solution to the ergonomic, low resolution and temperature issues relating to the then traditional stainless steel and copper test measures and visi-gauges. The first PUMPWATCH test measure was of a stainless steel construction with a very special Temperature Compensating device which with the use of Isopropyl Alcohol could counteract the effects of temperature fluctuation in the stainless steel. Attached to its own set of wheels, avoided the need for the user to carry 20L of fuel back to the off-set.

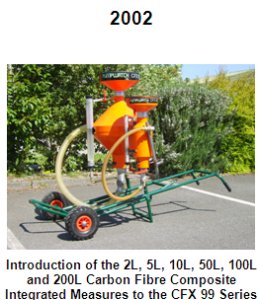

The new ‘integrated measure concept’ gave a much higher resolution to the user, making fuel dispenser testing a much easier task than ever before.   In 1997, following years of research and development, PUMPWATCH Ltd launched the world’s first Carbon Fibre Composite volumetric test measure. With its virtually zero coefficient of thermal expansion, it was the perfect solution to the issue of expansion and contraction of stainless steel with fluctuations in temperature. Suspended from its trolley, the high strength, non-denting and lightweight characteristics of the Carbon Fibre test measure have proven to be the ideal solution to the ergonomic issues during fuel dispenser testing procedures.  ![pw_lite_10l_test_measure_3.gif]center pw_lite_10l_test_measure_3.gif]center](/stg/userupload/site3262/pw_lite_10l_test_measure_3.gif) In 2002, the PUMPWATCH CFX 99 Series was developed to cater for the requirements of legal metrology services all over the world to carry out tests of varying volumes and speeds. The multi-measure packs allow tests to be carried out faster and with less errors while also taking health and safety of the user into consideration. The PW Lite concept was developed to meet the needs of the Trading Standards Officers who are required to carry out one-off checks at the request of the consumer, Service Engineers who may only require a single test measure when carrying out routine maintenance checks and the Service Station Manager/Owner who likes to keep track of how their nozzles are performing. |